Blast furnace, in short, is a kind of ironmaking equipment. Iron ore and coke enter from the top of the furnace in proportion, and high temperature blast (1000 ~ 1200 ℃) is carried out at the lower tuyere. Iron slag is produced by redox reaction in blast furnace. The slag and iron flow out from the lower taphole of the blast furnace to separate the slag, and the slag enters the slag ditch, slag flushing or dry slag pit. The hot metal enters the torpedo tank or continues to make steel or is sent to the cast iron machine through the swirl nozzle, and finally the blast furnace gas is discharged through the dust removal equipment, which is the whole process of blast furnace ironmaking.

With the development and progress of iron and steel industry in various countries, blast furnace is gradually developing in the direction of large-scale, high efficiency and long life. Accordingly, higher requirements are put forward for refractory materials of blast furnace lining. Such as good fire resistance, high temperature stability, density, thermal conductivity, wear resistance, corrosion resistance and slag resistance.

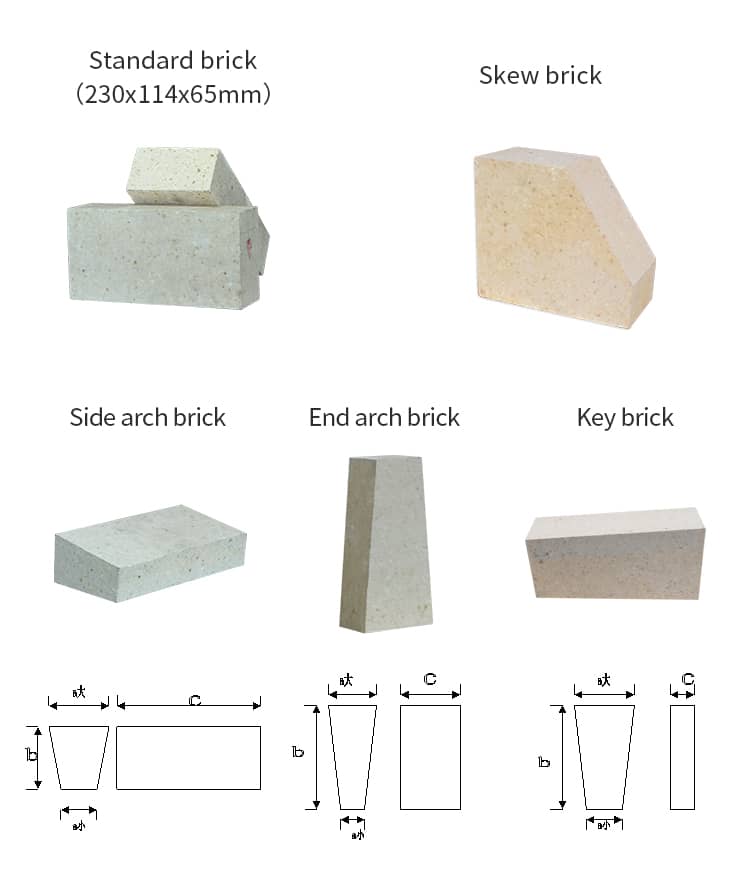

At present, there are many kinds of refractories used in blast furnace. Due to the influence of furnace conditions, the refractories used in various parts are not the same.

At the throat of the furnace, the refractory masonry is used as the protective lining, and the layout is reasonable. When the temperature is between 400 ℃ and 500 ℃, it is directly affected by the impact and friction of the burden, and the influence of air erosion is very small. Dense clay brick, high alumina brick, clay castable / spray coating can be used for masonry.

Blast furnace stack is an important part of blast furnace, which is used for heating, load reduction and slag dropping. The temperature of the upper and middle part of the furnace is 400-800 ℃, which is not affected by slag erosion. It is mainly affected by the erosion of ascending dust gas, thermal shock, alkali zinc and carbon deposition. Therefore, dense clay brick, high alumina brick, anti stripping and wear-resistant phosphate clay brick, high alumina brick and sillimanite brick are used in the middle and upper parts; The lower part of the furnace is built with dense wear-resistant clay brick, high alumina brick, corundum brick and silicon carbide brick.

The updraft of the bosh acts as a buffer, part of the burden is reduced to slag, and the lining is seriously eroded by iron slag. The temperature of the upper part is 1400-1600 ℃ and that of the lower part is 1600-1650 ℃. Therefore, refractory with strong slag erosion resistance and erosion resistance should be selected. Low porosity clay brick, high alumina brick, graphite brick, silicon carbide brick and corundum brick can be used for bosh.

The hearth is the filling part of molten iron and slag. The maximum temperature of tuyere zone is 1700-2000 ℃, and the bottom temperature is 1450-1500 ℃. The hearth lining is not only affected by high temperature, but also eroded by slag and hot metal. Corundum mullite brick, brown corundum brick and sillimanite brick can be used for hearth tuyere, corundum mullite brick and brown corundum brick can be used for slag iron contact hot surface, dense carbon brick, graphite semi graphite carbon brick, microporous carbon brick and molded carbon brick can be used for cold surface, brown corundum low cement prefabricated block can be used for side wall, and small carbon brick can be used for hearth hot pressing, Graphite semi graphite carbon brick can be used for furnace bottom microporous carbon brick.

Clay brick, silicon carbide brick, graphite brick, fused corundum castable, silicon carbide castable and hot gunning material can be used for blast furnace taphole. Low cement and high aluminum castable can be used for tap hole cover. The skimmer can use low cement corundum castable. The refractory of rotary nozzle is similar to that of tap hole. The threaded hole can be made of lower material.

Wechat Us

Wechat Us