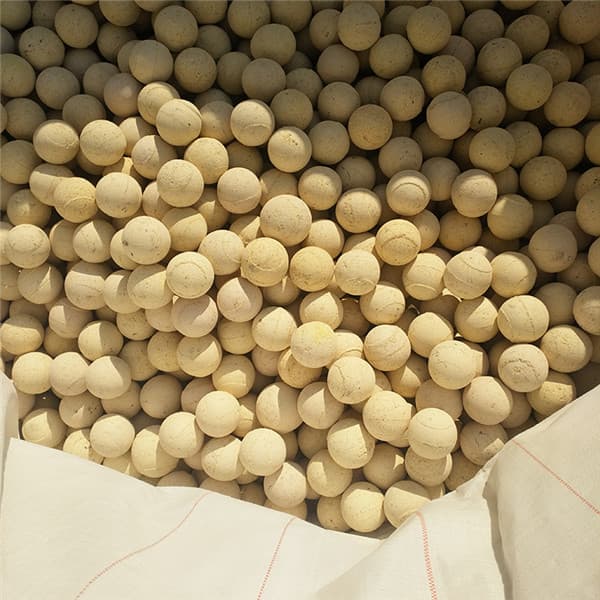

The content of Al2O3 of wear resistance corundum porcelain ball is between 90% and 99%. Its sizes include Ф6, Ф8, Ф9, Ф10, Ф15, Ф20, Ф25, Ф30, Ф40, Ф50, Ф60, Ф70 and customized sizes.

We mainly manufacture chemical filler ball and mill ball.

The filler ball is widely used in petroleum industry, chemical industry, fertilizer industry, natural gas industry, coal chemical industry, methanol industry and other industries as support covering material and tower packing of catalyst, molecular sieve, desiccant, thionizer and other parts in the reactor. It is of high temperature resistance, high pressure resistance, organic solvent erosion resistance (acid, alkali, salt and others), high mechanical strength, good chemical stability, etc.

Because of high mechanical strength and good wear resistance performance, mill ball is also widely used as the grinding media in sand mill of ball mill.

Physical & Chemical Indexes:

| Item | Series 90 | Series 92 | Series 95 | Series 99 |

| Al2O3 (%) | ≥90 | ≥92 | ≥95 | ≥99 |

| Fe2O3 (%) | ≤0.3 | ≤0.25 | ≤0.15 | ≤0.1 |

| Water Absorption (%) | ≤0.8 | ≤0.8 | ≤0.8 | ≤0.8 |

| Bulk & Density (g/cm3) | ≥2.8 | ≥3.0 | ≥3.1 | ≥3.2 |

| Pile Density (g/cm3) | ≥1.7 | ≥1.9 | ≥2.0 | ≤2.1 |

Wechat Us

Wechat Us