We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

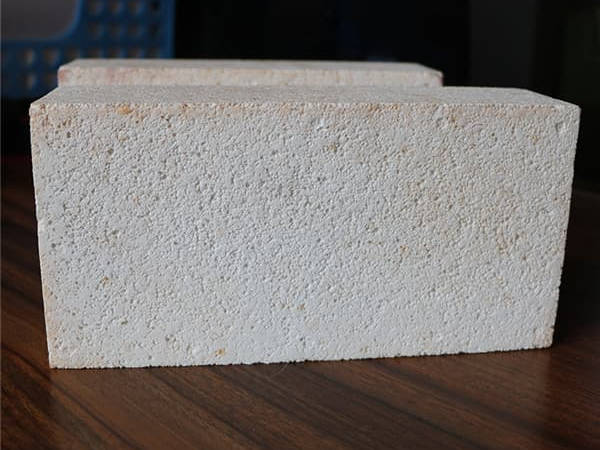

Product description of silica insulation bricks

Silica insulation bricks are insulating silica refractory products with SiO2 content above 90% and bulk density less than 1.2g/cm³. The mineral composition of silica insulating refractory brick is: 78%~86% of phosphor quartz, 13%~15% of square quartz and 4%~7% of quartz. Silica thermal insulation refractory bricks are generally made of crystalline quartzite or silica sand as raw materials, with flammable substances added to the ingredients, such as coke, anthracite, sawdust, carbonized rice husk or gas foaming method to form a porous structure.

Advantages of silica insulation bricks

Lightweight silica bricks have excellent refractory properties, load softening temperature close to dense silica bricks up to 1620 ℃, its thermal stability is better than dense silica bricks. Therefore, lightweight silica bricks can be used for a long time under high temperature conditions (1500-1550℃) without contacting with slag, suitable for large blast furnace supporting hot blast furnace lining, glass kiln gas insulation layer, etc.

Application of silica insulation bricks

Light weight silica bricks are suitable for: coke oven, hot blast furnace, glass melting kiln, carbon kiln, etc.

More relevant refractory products: Ceramic fiber blanket

Parameters of silica insulation bricks

| Item | QG-1.0 | QG-1.1 | QG-1.2 |

| SiO2 % | 91 | 91 | 91 |

| Refractoriness°C | 1680 | 1680 | 1670 |

| 0.2Mpa Refractoriness Under Load °C | 1480 | 1560 | 1560 |

| Cold Crushing Strength Mpa | 3.5 | 3.5 | 3.5 |

| True Density g/cm3 | 2.39 | 2.39 | 2.39 |

| Bulk Density g/cm3 | 1 | 1.1 | 1.2 |

| Permanent Linear Change On Reheating(%) | 0~+0.5 1450°CX2h | 0~+0.5 1550°CX2h | 0~+0.5 1550°CX2h |

| Thermal Conductivity (W/MK) 350°C | 0.55 | 0.6 | 0.65 |

Wechat Us

Wechat Us