CA50 is a hydraulic binder with an alumina content of approximately 50%.

The principal components of CA50 are calcium aluminates, which make it an ideal binder for refactory applications.

【Description】

The rheological properties of CA50 are well adapted for all types of placing methods, particularly for casting and gunning. It is recommended for applications where rapid hardening propertes and excellent mechanical performances.

KERUI CA50 products are manufactured by sintering process in rotary kiln, represented by three product types A600. A700 and A900.

CA50-A600: A600 product has rapid hardening properities and high hydration exothermic rate, it’ s widely recommended for conventional high cement castables such as high performance alkali resistance castables, high alumina castables and slag-stopping ball, etc.

CA50-A700: In comparison with A600, A700 product has lower impurities level, stable hardening properties and rapid strength development, it is recommended mainly to be used in low cement castables.

CA50-A900: A900 product is produced with selection of high purity materials, the alumina content of A900 is higher than other grades, and impurity oxides as like SiO2, Fe203 content is lower than that of A600 and A700. So, it is widely recommended for applications where stable hardening properties, good working ability and excellent mechanical performance are required.

Notes: refractory cement = high alumina cement = Calcium aluminate cement

【Physical and chemical indicators】

| Brand | A600 | A600 | A700 | A700 | A900 | A900 |

| Refractory cement Types | Usual range | Specification limit | Usual range | Specification limit | Usual range | Specification limit |

| SiO2, % | 7.8-8.3 | ≤9.0 | 7.0-7.5 | ≤8.0 | 5.0-5.5 | ≤6.0 |

| Al203, % | 50.0-51.0 | ≥50.0 | 50.5-51.5 | ≥50.0 | 53.5-54.5 | ≥53.0 |

| Fe203, % | 1.5-2.5 | ≤3.0 | 1.5-2.5 | ≤3.0 | 1.5-2.0 | ≤3.0 |

| R20, % | – | ≤0.5 | – | ≤0.5 | – | ≤0.5 |

| S-, % | – | ≤0.2 | – | ≤0.2 | – | ≤0.2 |

| CI-, % | – | ≤0.06 | – | ≤0.06 | – | ≤0.06 |

| 325M(%) | – | ≤20 | – | ≤15 | – | ≤8 |

| Specific surface areas, ㎡/kg | – | ≥320 | – | ≥350 | – | ≥380 |

| Setting time, min | ||||||

| Initial setting time IS | 50-120 | ≥30 | 50-120 | ≥30 | 150-210 | ≥150 |

| Final setting time FS | 90-180 | ≤360 | 120-210 | ≤360 | 210-300 | ≤360 |

| Flexural strength, Mpa | ||||||

| 1d | – | ≥5.5 | – | ≥6.5 | – | ≥8.5 |

| 3d | – | ≥6.5 | – | ≥7.5 | – | ≥9.5 |

| Compressive strength, Mpa | ||||||

| 1d | 45-55 | ≥40 | 50-60 | ≥50 | 70-75 | ≥70 |

| 3d | 50-60 | ≥50 | 60-65 | ≥60 | 80-85 | ≥80 |

【Additional Information】

Principal phase: CA

Secondary phase: C12A7、C2AS、CT

Pyrometric cone equivalent: 1400-1450℃

Bulk density: 900-1000kg/m3

Specific gravity: 2.9-3.1g/cm3

Shelf Life: 3 months

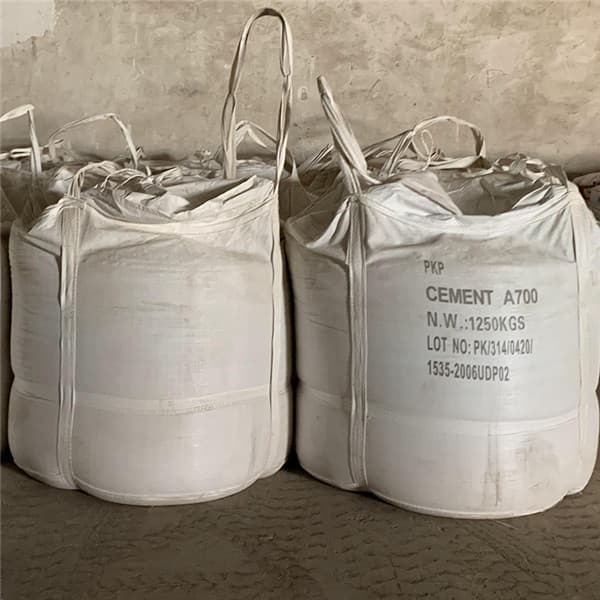

【Packaging and Storage】

Packing method: Standard export packaging

Paper bags: 25/50kg

Big bags: 1.0/1.5mt

Storage tips: Calcium aluminate cement CA50 must be stored in dry conditions, off the ground. In this case, it will retain its properties for at least 2 months. In many instances. experience has demonstrated that properties are retained for more than 3 months.

Wechat Us

Wechat Us