We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

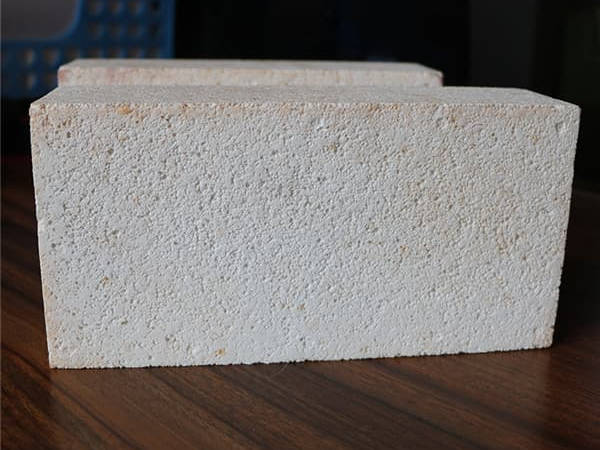

1.Product introduction of silica insulation brick

Light silica brick is made of quartzite material, with SiO2 content of about 91%, which has good acid slag resistance and low thermal conductivity. SiO2 has different types of crystals at different temperatures, and the transformation between crystals will cause changes in structure and density. Therefore, the change of silica crystal is closely related to the properties and uses of silica bricks.

2. Advantages of silica insulation brick

Light silica brick has excellent fire resistance. The load softening temperature is close to that of dense silica brick, reaching 1620 ℃, with only small residual expansion, and its thermal stability is better than that of dense silica brick. Therefore, light silica brick can be used for a long time under high temperature (1500-1550 ℃) without contacting with slag.

3.Parameters of light weight silica insulation brick

| Item | QG-1.0 | QG-1.1 | QG-1.2 |

| SiO2 % | 91 | 91 | 91 |

| Refractoriness°C | 1680 | 1680 | 1670 |

| 0.2Mpa Refractoriness Under Load °C | 1480 | 1560 | 1560 |

| Cold Crushing Strength Mpa | 3.5 | 3.5 | 3.5 |

| True Density g/cm3 | 2.39 | 2.39 | 2.39 |

| Bulk Density g/cm3 | 1 | 1.1 | 1.2 |

| Permanent Linear Change On Reheating(%) | 0~+0.5 1450°CX2h | 0~+0.5 1550°CX2h | 0~+0.5 1550°CX2h |

| Thermal Conductivity (W/MK) 350°C | 0.55 | 0.6 | 0.65 |

Wechat Us

Wechat Us