High Alumina Refractory Brick is made by high sintering selected bauxite chamotte by advanced process with strict quality control at 1420-1530℃.

According to the refractory temperature, High alumina refractory brick is divided into (international label): SK-32, SK-34, SK-36, SK-37, SK-38.

High Alumina Refractory Brick Performance Characters:

- High temperature resistant.

- Chemical erosion resistant.

- Slag resistance.

- Thermal stability.

High Alumina Refractory Brick Applications:

- Furnaces of metallurgy industry, heat treatment furnace.

- Furnaces of chemical industry and construction industry.

- Furnace of incineration of garbage, recirculating fluidized bed furnace.

- Coke oven, blast furnace, hot blast stove, steel barrel, casting system, boiler, cement kiln, glass kiln and various furnace lining and thermal equipment, etc.

| Item/Grade | SK-36 | SK-37 | SK-38 | SK-40 |

| AL2O3% (≥) | 55 | 65 | 70 | 82 |

| Fe2O3% (≤) | 2 | 2 | 2 | 2 |

| Refractoriness(SK) | 36 | 37 | 38 | 40 |

| Refractoriness underload, 0.2MPa, °C (≥) | 1450 | 1480 | 1530 | 1600 |

| Apparent porosity (%) | 20-23 | 20-23 | 20-22 | 18-20 |

| Bulk density (g/cm³) | 2.25-2.4 | 2.3-2.5 | 2.4-2.6 | 2.5-2.7 |

| Cold crushing strength ,MPa (≥) | 45 | 50 | 60 | 70 |

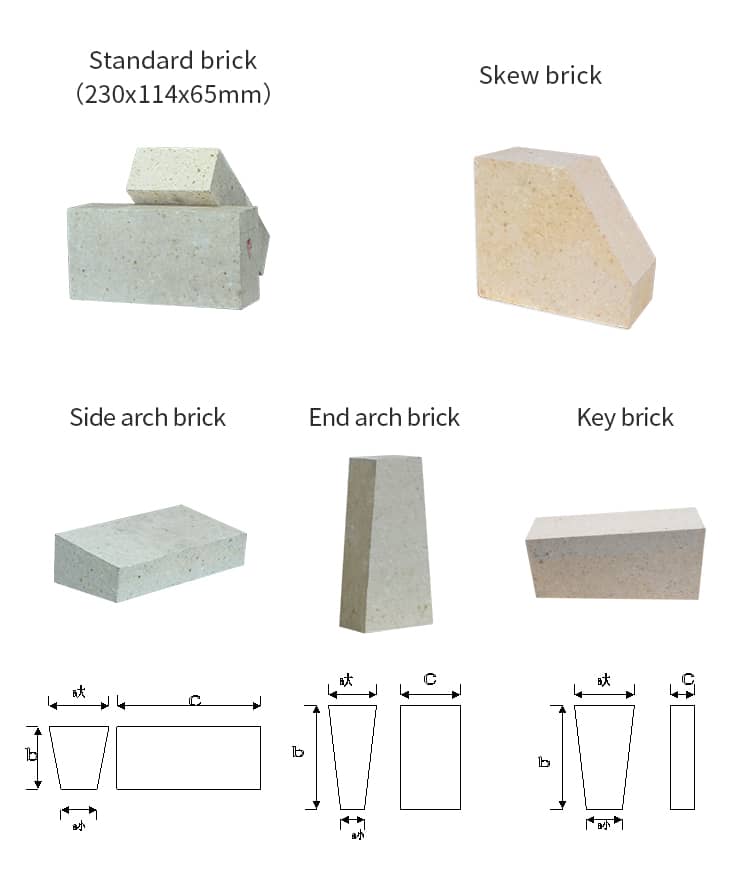

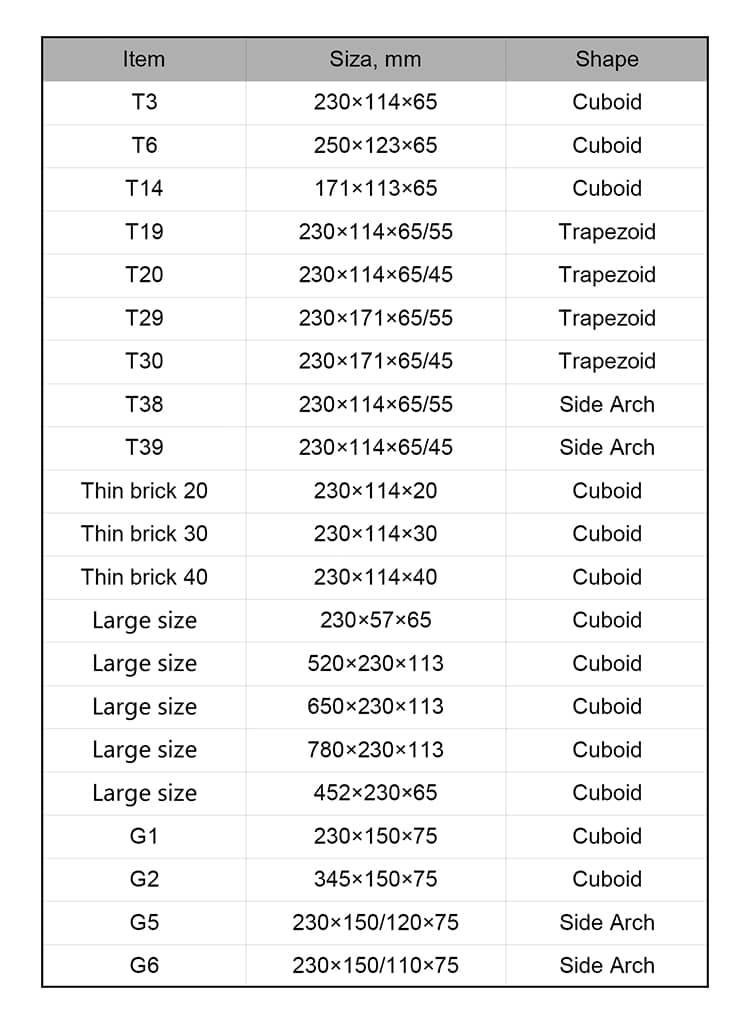

High Alumina Refractory Brick Standard size:

High alumina refractory brick is widely used in kiln masonry. The size of high alumina refractory brick is related to the calculation of kiln masonry consumption. Generally speaking, the standard size of high alumina refractory brick is 230*114*65mm, and the model is T3. Besides the standard brick, there are many other sizes. Also can be customized on color, size and shape, ect. Welcome to OEM and ODM.

Wechat Us

Wechat Us