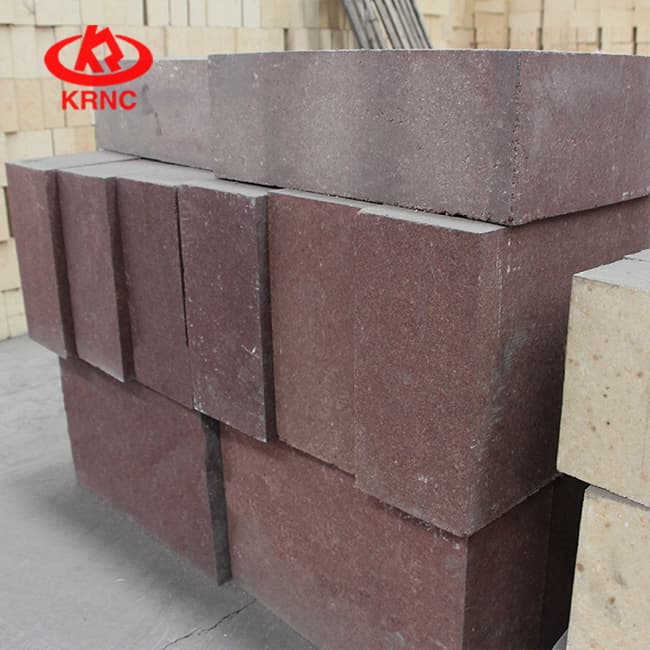

Magnesia brick descripetion

Magnesia bricks, also known as magnesite bricks, are refractory bricks made mainly of magnesium. It is a high-quality product with excellent thermodynamic performance, widely used in various industries such as steel, cement, glass, non-ferrous metals, etc.

Magnesia brick properties

Magnesium bricks have several advantages compared to other refractory materials.

- Firstly, it has excellent thermal shock resistance, which means it can withstand rapid temperature changes without cracking or peeling.

- Secondly, it has high fire resistance, which means it can withstand high temperatures without melting or degradation.

- Thirdly, it has high compressive strength, which means it can withstand heavier loads without cracking or fracture.

- Fourthly, it has good chemical resistance, which means it can withstand corrosive environments without being damaged.

- Finally, it has good dimensional stability, which means that it can maintain its shape and size even at high temperatures.

Magnesia brick application

Magnesium bricks are widely used in various high-temperature applications due to their excellent thermodynamic properties.

In the steel industry, it is usually used as a lining material for steelmaking furnaces and ladles, which can withstand high temperatures and corrosive environments.

In the cement industry, it is used as a lining material for high-temperature equipment such as rotary kilns.

In the glass industry, it is used as a lining material for glass melting furnaces and a production material for glass wool.

In the non-ferrous metal industry, it is used as a lining material for copper and nickel smelting furnaces.

Magnesia brick manufacturing Process

The manufacturing process of magnesium bricks includes several steps such as raw material preparation, stirring, forming, drying, and firing.

- The raw materials are first crushed and ground into fine powder, and then mixed with water to form plastic blocks.

- Then, the substance is shaped into the desired shape and dried at high temperature to remove moisture.

- Finally, molded bricks are fired at high temperatures in the kiln, usually around 1600-1800 ° C, to achieve the required performance.

Wechat Us

Wechat Us