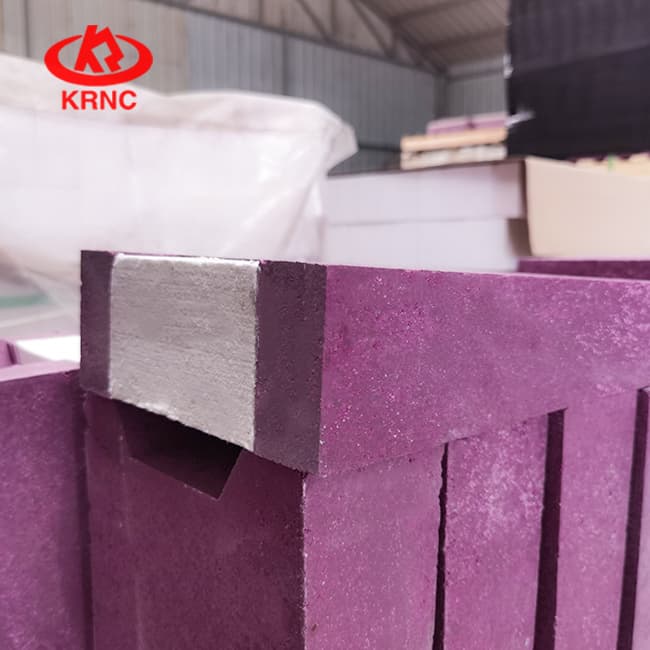

Chrome corundum bricks are made of α-Al2O3 as raw material, adding proper amount of chrome oxide powder and fine powder of chrome corundum clinker, forming, burning at high temperature, the content of chrome oxide is 1%~30%. Corui chrome corundum brick is accurate size, while also supporting custom refractory products. Corui chrome corundum brick has excellent high temperature creep resistance and wear resistance, high temperature resistance, good thermal shock.

Chrome corundum bricks description

Chrome corundum refractory bricks refer to the refractory products containing Cr2O3. At high temperature, Cr2O3 and Al2O3 form continuous solid solution. There are two kinds of chrome corundum brick: fused cast chrome corundum brick and sintered chrome corundum brick. In general, chrome corundum brick refers to sintered chrome corundum brick.

Chrome corundum bricks index

| Chrome corundum brick | 15 Chrome-Corundum Brick | 10 Chrome-Corundum Brick | 5 Chrome-Corundum Brick | Wear Resistance Skid Rail | Zr-Cr-corundum Brick |

| Cr2O3, % | ≥15 | ≥10 | ≥5 | ≥5 | ≥8 |

| AL2O3, % | ≥75 | ≥80 | ≥85 | ≥85 | ≥60 |

| ZrO2, % | | | | | ≥15 |

| Apparent porosity, % | ≤18 | ≤18 | ≤18 | ≤16 | ≤18 |

| Bulk density, g/cm³ | ≥3.35 | ≥3.3 | ≥3.2 | ≥3.2 | ≥2.9 |

| Cold crushing strength, MPa | ≥100 | ≥100 | ≥100 | ≥100 | ≥90 |

| Refractorines under load, 0.2MPa,0.6% | ≥1700 | ≥1700 | ≥1700 | ≥1700 | ≥1700 |

Production process of chrome corundum bricks

Chrome corundum refractory brick usually refers to sintered chrome corundum brick, which takes α-Al2O3 as raw material, adds appropriate amount of chrome oxide powder and chrome corundum clinker fine powder, is formed and burned at high temperature. The chromium oxide content of sintered chrome rigid brick is generally lower than that of fused cast chrome corundum brick. It can also be prepared by mud casting method. The α-Al2O3 powder and chromium oxide powder are evenly mixed, and the degumming agent and organic binder are added to make thick mud. At the same time, some chromium corundum clinker is added, and the brick billet is made by grouting method and then fired.

Notes

Chrome corundum refractory bricks used in petrochemical industry gasifiers should be low in silicon, iron, alkali, high purity, but also have high density and strength. The content of Cr2O3 is mostly in the range of 9%~15% for chrome corundum products which are widely used.

Chrome corundum brick price

Chrome corundum brick is generally divided into fused cast chrome corundum refractory brick and sintered chrome corundum brick, chrome corundum brick production process is different, the price is also different. So it makes a big difference when you ask different manufacturers to quote you. Corainite recommends that you choose the appropriate chrome corundum brick according to the location of the kiln, which can improve the service life of your kiln, but also reduce your cost.

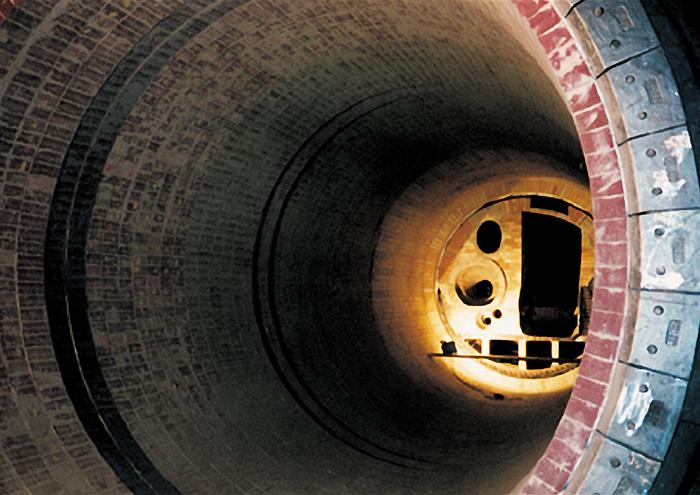

Application of chrome corundum bricks

Chrome corundum refractory brick can be used as the lining of glass kiln, the cover brick of brushed glass flow hole, and the backing of hot metal pretreatment device, waste incinerator, coal water slurry pressure gasifier, etc.

China chrome corundum bricks manufacturer

The purpose of Kerui Refractory is to serve the global high-temperature industry. If you currently have a high-temperature equipment construction project and need high-quality chrome corundum refractory bricks for masonry, Kerui refractory manufacturer is willing to provide you with free professional refractory consulting services. Kerui Refractory is a reliable refractory manufacturer for customers, and also hopes to become your best partner in China.

Wechat Us

Wechat Us