We are a refractory material manufacturer, with four major factories: heavy brick factory, light brick factory, monolithic refractory factory and fused-cast brick factory.

We promise to provide you with high-quality refractory materials.

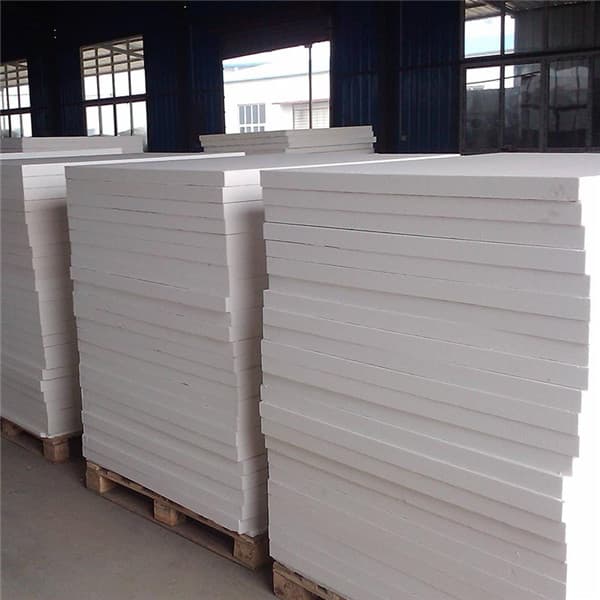

Product introduction of ceramic fiber board

Ceramic fiber board made of refractory materials. Even after heating, good mechanical strength is maintained, and the product is harder. Felt is a fiber insulation product, which maintains strength. The main raw materials are emerald and alumina.

Features of ceramic fiber board

- Advantages of ceramic cellulose:

- Excellent wind resistance

- Low heat capacity and thermal conductivity

- The material is not fragile and flexible

- Precise size, flat stoping

- High strength and long life

- Easy to install and build

- Continuous production, uniform fiber distribution, stable performance.

Applications of ceramic fiber board

- Lining used to keep the furnace warm for the production of cement and other building materials

- Stone furnace, metallurgical furnace, ceramic furnace, glass furnace and holding furnace

Heat treatment furnace lining 3

Non ferrous metal production keeps back warm - Thermal reaction and heater insulation

More relevant refractory products: Silica insulation bricks

Parameters of ceramic fiber board

| Type | Ordinary | Standard | High Purity | High Alumina | Zirconium |

| Classification temperature, ℃ | 1100 | 1260 | 1260 | 1360 | 1430 |

| Working temperature, ℃ | <1000 | 1050 | 1100 | 1200 | 1350 |

| Colour | white | Pure white | Pure white | Pure white | Pure white |

| B.D, kg/m3 | 260-320 | 260-320 | 260-320 | 260-320 | 260-320 |

| PERMANENT liner change, % 24Hours under ,B.D320kg/m3 | -4 (1000℃) | -3 (1000℃) | -3 (1100℃) | -3 (1250℃) | -3 (1350℃) |

| HEAT CONDUCTIVITY COEFFICIENT w/m·k | 0.085(400℃) | 0.085(400℃) | 0.085(400℃) | 0.085(400℃) | 0.085(400℃) |

| B.D, 285kg/m3 | 0.132(800℃) | 0.132(800℃) | 0.132(800℃) | 0.132(800℃) | 0.132(800℃) |

| B.D, 285kg/m3 | 0.180(1000℃) | 0.180(1000℃ ) | 0.180(1000℃) | 0.180(1000℃) | 0.180(1000℃) |

| STRENGTH EXTENSION, Mpa, THICKNESS SHRINKAGE 10% | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Al2O3 | 44% | 46% | 47~49% | 52~55% | 39~40% |

| Al2O3+SiO2 | 96% | 97% | 99% | 99% | – |

| Al2O3+SiO2+ZrO2 | – | – | – | – | 99% |

| ZrO2 | – | – | – | – | 15~17% |

| Fe2O3 | <1.2% | <1.0% | 0.2% | 0.2% | 0.2% |

| Na2O+K2O | ≤0.5% | ≤0.5% | 0.2% | 0.2% | 0.2% |

Wechat Us

Wechat Us