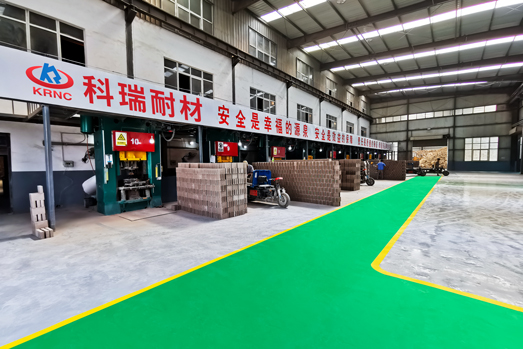

High alumina refractory bricks are a common refractory produced and marketed by Kerui company, the main component is Al2O3. High alumina fire bricks have the properties of high strength, corrosion resistance and high temperature resistance. Kerui manufacturer supports customized unshaped brick, other manufacturers can not do high aluminum shaped brick, Kerui manufacturers can do.

So how can I buy high alumina refractory brick near me? Hope this article helps you.

First you need to have a basic understanding of high alumina bricks:

What are high alumina refractory bricks?

High alumina brick is a kind of neutral refractory with alumina content above 48%. It is made of alumina or other raw materials with higher alumina content by molding and calcination. High thermal stability, fire resistance above 1770℃. Good slag resistance, high thermal stability, refractoriness above 1770℃. Good slag resistance.

According to the different Al2O3 content, high alumina fire bricks can be divided into three grades:

The Al2O3 content of primary high alumina brick is more than 75%.

The Al2O3 content of secondary high alumina brick is 60~75%.

The Al2O3 content of tertiary high alumina brick is 48~60%.

High alumina brick properties

High alumina fire bricks belong to high-grade refractory material, refractoriness is higher than clay brick and semi-silicon brick, up to 1750~1790℃.

Due to more Al2O3 and less impurity in high aluminum products, the softening temperature under load is higher than that of clay bricks.

High alumina refractory bricks have more Al2O3, which can resist the erosion of acid slag and alkaline slag.

Production technology of high alumina fire bricks

High aluminum clinker is strictly selected before crushing, and stored by classification, using bauxite clinker and combined clay common fine grinding method, such as first and second high aluminum brick with tunnel kiln firing is generally 1500 ~ 1600℃.

High aluminum refractory bricks price

Compared with refractory fire clay bricks, high alumina refractory bricks price is higher. However, Kerui Company, as a refractory high alumina brick manufacturer, will not only provide cheap high alumina fire bricks for customers, but also ensure the quality of high alumina brick products.

High alumina brick application

High alumina brick is mainly used for the lining of blast furnace, hot blast furnace, electric furnace top, blast furnace, reflector furnace and rotary kiln.

Finally, how to buy high quality alumina refractory bricks?

First, no matter what type of furnace you plan to build, high quality refractory high aluminum bricks must be your first choice. If you buy firebrick locally, you can check whether the firebrick manufacturer you choose can provide you with the firebrick you need. Moreover, buying locally can save you long distance freight.

Second, no matter where you decide to buy refractory materials, you should know the actual situation of multiple refractory suppliers. First you need to know what kind of firebrick you need through the website of the refractory manufacturer, and then you can compare the quality and price of the firebrick.

Third, if you can’t find the right firebrick locally, you can also buy firebrick from abroad, such as the Kerui Refractory factory in Zhengzhou, China. We can provide you with professional advice on purchasing firebrick as well as construction. In addition, we can also send professional engineers to your country to help you design and build your kiln.

Kerui now sells a variety of high alumina refractory bricks. Contact us for a free quote.

Wechat Us

Wechat Us